Easy MTP integration enables modular manufacturing, reduces capital and operating costs and accelerates automation deployment

AUSTIN, Texas (June 3, 2021) – Today Emerson announced the integration of the emerging MTP process automation standard into its control systems, as part of a continued effort to help manufacturers increase speed-to-market and reduce project and operations costs. Emerson is among the first automation vendors to support the User Association of Automation Technology in Process Industries’ (NAMUR) Module Type Package (MTP) standard for both distributed control systems (DCS) and programmable logic controllers (PLCs).

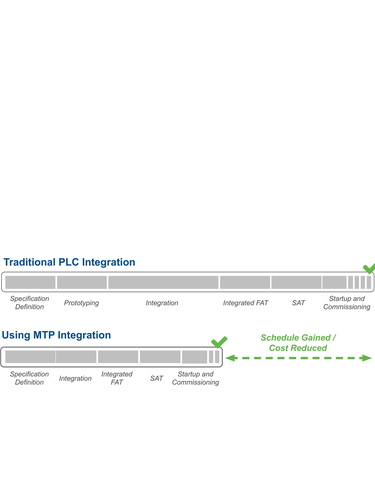

A key challenge for the process industries, particularly life sciences and chemical, is the time it takes to bring products to market or change operations to accommodate new products. With many process changes, engineers can spend weeks or longer integrating manufacturing skids and their respective automation systems. Working with industry leaders like Emerson, NAMUR has been developing MTP to create a common, open standard that requires less engineering and makes new equipment integration closer to plug-and-play. With its MTP tools, Emerson estimates manufacturers and system integrators could save weeks in project time and hundreds of thousands of dollars in engineering costs compared to traditional integration without MTP.

“MTP is a significant step to help the manufacturing industries respond faster to changing markets. With our MTP implementation, Emerson is continuing a tradition of not only supporting but innovating on industry standards. Integration between our DeltaV and PACSystems automation systems as well as third-party automation systems will help create more modular, flexible manufacturing that improves speed to market for our customers,” said Sean Sims, vice president of marketing for the DeltaV platform, Emerson.

By incorporating MTP into its DeltaV™ and PACSystems™ automation systems, Emerson has eliminated the requirement for end users or system integrators to invest in additional engineering or special integration tools. Emerson’s MTP tools natively create a configuration file for its PACSystems PLCs and AMS machinery prediction devices that is automatically integrated into the DeltaV DCS. PACSystems and DeltaV systems both support integration with third-party components or orchestration layer systems that have also implemented support for MTP.

With MTP, organizations can reduce engineering time and risk for both capital and operational performance projects, making it easier to quickly deliver critical products to market. In the pharmaceutical and biotech industries, MTP helps enable “ballroom-style” flexible manufacturing where skids can be interchanged with minimal re-engineering. More flexible manufacturing means production sites can switch skids faster to produce different therapies based on patient demand.

As part of the first MTP release, Emerson has also taken a significant step to make reliability data from its manufacturing units importable to the DeltaV system. Operators can use the asset health data from the AMS Asset Monitor edge analytics device to consider how the health of plant asset will impact operations and production.